erica@bkdxm.com

How to Work With Us

Our Process from File to Finished Part

01

Upload CAD File

Submit CAD Drawings And RFQs With Part specs And Application Details To Get Fast Engineering Support.

02

Review & Quote

Receive Pricing And DFM Feedback To Ensure Your Design ls Ready For Manufacturing

03

Start Production

We Begin Machining Or Molding With Selected Materials And Strict Quality Standards.

04

Parts Delivered

Parts Are Carefully inspected, Securely Packed, And Shipped On Time-ready For Your Next Stage.

erica@bkdxm.com

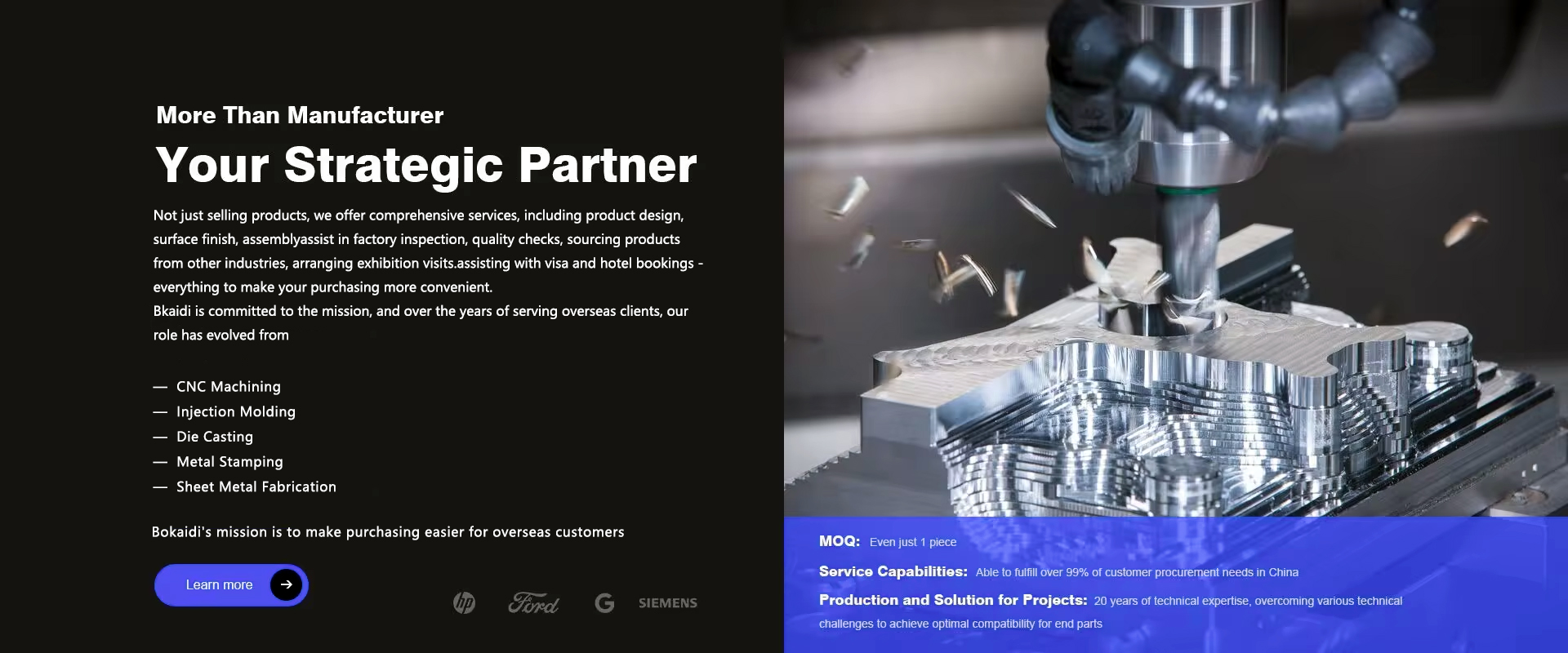

Our Manufacturing Capabilities

BKD Provides A Range Of Manufacturing Capabilities To Support Rapid Prototyping And Both Low And High-Volume Production Needs. With Our Own Factory And A Reliable Chinese Network, We Deliver Complex, High-Quality Parts Efficiently.

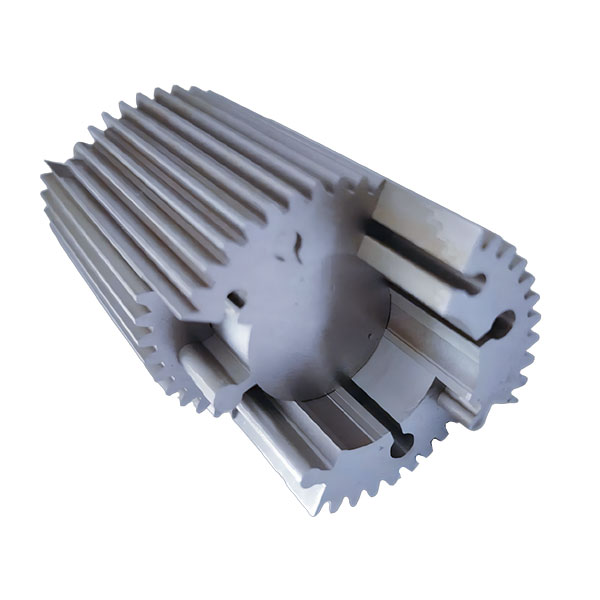

CNC Machining Service

CNC Milling, Turning And Precision Machining. We Can Make Prototypes And End-Use Parts With Precise And Complex Designs.

Tolerances As Tight As ±0.001In (0.025mm)

Wall Thickness As Thin As 0.020 In (0.5mm)

Lead Times Starting At Just 1Day

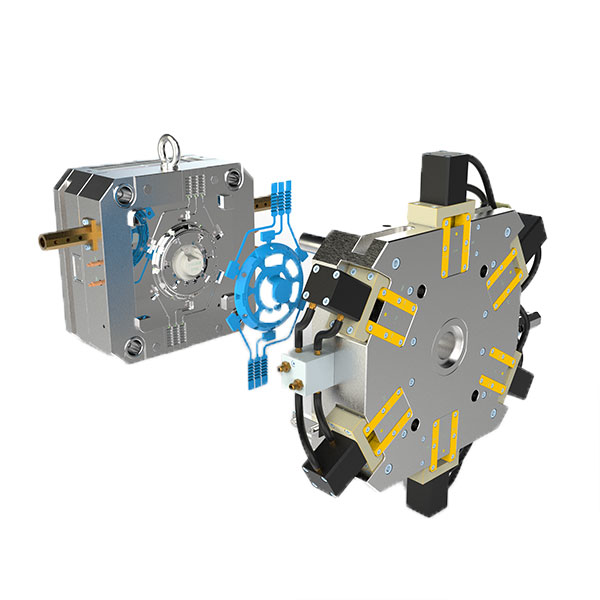

Mold

As A Molding Tool, Used To Mass-Produce Industrial Product Parts With Specific Shapes And Sizes.

Tolerances As Tight As +0.02-+0.005 mm

Die Casting

Choose From Aluminum,Zinc, Magnesium, Copper. High Precision Die Cast Metal Parts For High-Volume Needs.

Minimum Batch:500 Pcs

Minimum Wall Thickness:0.03 In.(0.8mm)

Injection Molding

Plastic Injection Molding, Rapid And Production Tooling, Overmolding, And Insert Molding. No MOQ Required, All While Maintaining Consistent Quality.

T1 Samples As Fast As 2 Weeks

To 1M Pcs

Sheet Metal Fabrication

Laser Cutting, Bending, Welding, Punching, Riveting, Stamping. We Offer Flexibility To Create Precise Sheet Metal Prototypes And Production Parts.

Lead Times From 3 Days

Wall Thickness As Thin As0.008 In (0.2mm)

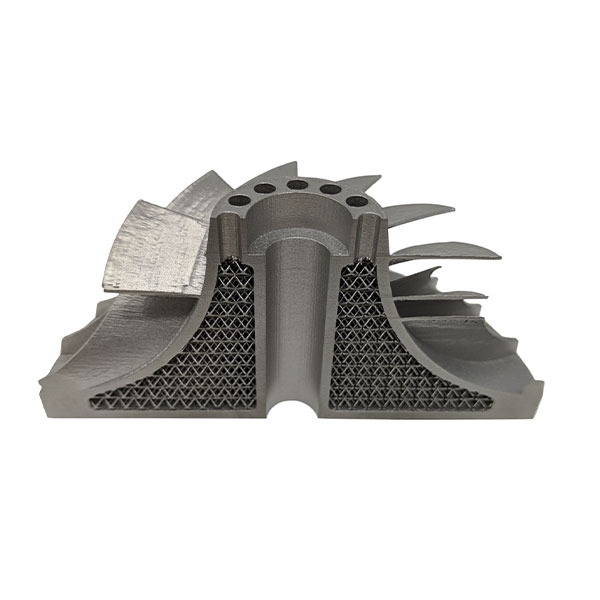

3D Printing

SLA, HP MJF, SLS,SLM Technologies For Functional Prototyping And Low- Volume Production.We Manufacture 3D Printed Parts At Competitive Price.

Tolerances As Fine As ±0.008 In (+0.2Mm).

Metal And Plastic 3D Printing

Lead Times From 1Day

Vacuum Casting

Fast And Cost-Effective Short-Run Production For Plastic Prototypes Using Soft Tooling, A Great Alternative To Low- Volume Injection Molding.

Precision To Reach ±0.002In (±0.05mm)

Wire EDM

Sinker And Wire EDM Machining. We Can Machine Sharp Inside Corners, Thin Walls, And Burr-Free Parts.

Small Parts Tolerance Down To ±0.0002In(±0.005 mm)

Small Parts Tolerance Down To ±0.0002In(±0.005 mm)

Trusted by Top Brands Worldwide

About Our Company

Xiamen Bokaidi Precision Technology Co., Ltd. located in Xiamen, China, a beautiful port city, has its own affiliated factories. passed ISO 9001:2015, can provide OEM and ODM one-stop service with low MOQ 1piece.

To better control product quality, we have introduced over 50 imported machines and advanced automatic spraying systems, ensuring that the entire production process from mold design, mold making, product manufacturing, surface treatment,to final assembly is completed seamlessly within our company, forming a fully integrated and optimized production cycle.

Bokaidi (Xiamen) dedicated to delivering premium-quality products and services across various industries, including automotive, aerospace, new energy, medical devices, furniture, and robotics etc.Sincerely looking forward to working with you together, Let’s endeavor together to create a better future.

OEM/ODM Service

We have always been committed to designing products and solutions that improve people's quality of life.

OEM Service

When you put forward your needs, our engineers will provide you with faster and more perfect customized solutions. We have a wide range of products, and we will provide technical support according to your actual needs to choose the right product for you.

ODM Service

We provide 24-hour online service and strictly control quality management from the day of placing the order. We conduct regular product inspections and spot checks every day to ensure that every batch of goods shipped is qualified.

Logo

Package

Colors

Materials

Communicating

Colors

Materials

Application Areas

Our products are used in many industries

Automobile Industry

Robotics Industry

Medical Device

Marine Industry

Automation Equipment

Aerospace

What Our Customers Said

A Customer's Words Mean More Than Ours See What Our Satisfied Customers Have Said About How We Fulfilled Their Requirements.

Liam Anderson

Very Satisfied With My Order! The supplier Was Very HelpfulWith Making Design Suggestions And Changes, And The Products Came 0ut Great.The Priding Was very Fair As Well. Thank You, And Thanks Erica For Being So Helpful!

Gabriel Rossi

Good Quality Bought From There Multiple Times Many Quantities Parts For Wheelchairs Out Of USA.

Arjun Patel

Nice Quality And Very Professional.Also They Send Me The Measurment Check Reports Of AllParts .ust like lt Should B..Get The Parts And Assembled it RightAway .Everything Like On My Drawings …. ove lt !!

Ethan Carter

The product l Received Was 0f The High Qualty CNc Machining:l Am So Pleased To Have Kassie from DAZA0 For CNc Services. uper fast ProfessionalSenvice EveryDetail Was Applied Flawlessly ! This ls Such A Blessing For My Business!!!

Sofia lvanova

Workine With Maegie & Xamen DAZA0 CNcls Alwavs Friendy And Professional.l Alwavs Have Gotten Great Communication And Superblv Machined Parts, We AreCommitted To Xiamen DAZAO For The Future Of Our Supply Chain.